Xúc tác palladium HONGBO, Chất hoạt hóa sàng phân tử, Chất hút ẩm sàng phân tử cho nhà máy sản xuất hydro

Để đảm bảo hiệu suất ổn định của chất xúc tác palladium và ngăn ngừa độ ẩm, ô nhiễm hoặc hư hỏng trong quá trình vận chuyển và bảo quản, các phương pháp đóng gói và bảo quản chuyên nghiệp được áp dụng: chất xúc tác được đóng gói kín trong túi nhựa hai lớp, lớp trong là túi PE chống rò rỉ và chống thấm nước, lớp ngoài là túi nylon chống mài mòn và chống ẩm, có thể cách ly hiệu quả không khí, độ ẩm và tạp chất; chất xúc tác được đóng gói kín được đặt trong thùng carton dày hoặc thùng sắt, miệng thùng được niêm phong bằng nắp đậy, thân thùng được ghi rõ tên sản phẩm, thông số kỹ thuật, ngày sản xuất, hạn sử dụng và các thông tin khác, đồng thời trang bị vật liệu đệm chống sốc để tránh va chạm và hư hỏng các hạt chất xúc tác trong quá trình vận chuyển. Trong quá trình bảo quản, chất xúc tác được đóng gói cẩn thận cần được đặt trong kho khô ráo, thông gió và mát mẻ, tránh xa nguồn nước, nguồn lửa và các chất ăn mòn, để tránh sự suy giảm hoạt tính của chất xúc tác do môi trường ẩm ướt và nhiệt độ cao; đồng thời, nghiêm cấm việc ép và va chạm các thùng đóng gói để tránh làm vỡ vụn các hạt chất xúc tác; Chất xúc tác chưa mở có thể có thời hạn sử dụng 12 tháng trong điều kiện bảo quản quy định và nên được sử dụng càng sớm càng tốt sau khi mở để tránh tiếp xúc lâu dài với không khí ảnh hưởng đến hiệu suất.

The custom-made palladium catalyst for hydrogen production produced by Hongbo belongs to the Pd-Al₂O₃ supported catalyst type. It uses high-purity activated alumina (Al₂O₃) as the carrier, uniformly loads precious metal palladium (Pd) on the surface of the carrier, and is made through special molding and roasting processes, with excellent catalytic activity and structural stability. This catalyst is mainly used in hydrogen production processes, and its core function is to remove oxygen impurities from hydrogen. At the same time, it can realize hydrogenation and deoxidation treatment of inert gases such as nitrogen, argon, and ammonia, ensuring the purity of hydrogen products and meeting the strict requirements of subsequent production processes. Its core reaction principle is catalytic hydrogenation and deoxidation reaction: when the feed gas containing oxygen impurities passes through the catalyst bed at a constant speed, under the catalytic action of the catalyst, the oxygen impurities in the gas combine with hydrogen to form harmless water (reaction equation: 2H₂ + O₂ → 2H₂O), and the water can be completely removed through the subsequent dehydration process, thus achieving the purpose of deep deoxidation. Compared with ordinary deoxidizers, this palladium catalyst deoxidizer has three significant advantages: high catalytic activity, which can start the reaction at a lower temperature and maintain stable deoxidation efficiency; excellent physical properties, no pulverization or agglomeration during use, high mechanical strength, which can effectively avoid bed blockage caused by catalyst particle damage; long service life, which can operate stably for a long time, greatly reducing replacement costs and shutdown losses.

Technical Performance and Parameters

The technical performance and parameters of Hongbo Pd-Al₂O₃ type palladium catalyst have been strictly tested and optimized to adapt to various hydrogen production process scenarios. The specific parameters are as follows:

Height-diameter ratio of catalytic reactor: ≥3:1. This ratio is optimized through hydrodynamic calculation, which can ensure that the feed gas passes through the catalyst bed uniformly, avoid channeling and bias flow, extend the contact time between gas and catalyst, give full play to the catalytic effect, and ensure the stability of deoxidation effect.

Service temperature: The catalytic reaction can be started at room temperature without high-temperature preheating, which greatly reduces energy consumption; if properly heated (it is recommended to heat to 50-100℃), the catalytic activity can be further improved, the reaction rate can be accelerated, the deoxidation depth can be better, and it can adapt to the use requirements of different working conditions.

Space velocity: 2000~8000hr⁻¹. The space velocity has a wide adaptation range and can be flexibly adjusted according to the actual working conditions such as feed gas treatment capacity and oxygen content. Within this space velocity range, the catalyst can maintain stable deoxidation performance, which not only meets the needs of large-scale continuous production but also adapts to small-batch and high-precision hydrogen production scenarios.

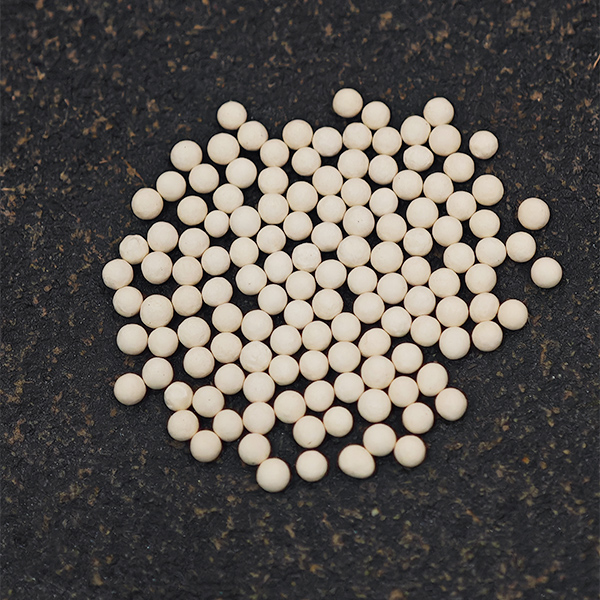

Particle size: Two specifications are available, namely ∮3~5mm and ∮4~6mm. The particles are spherical with smooth surface and good fluidity, which are easy to load and replace; the reasonable particle size design can balance the bed resistance and contact area, not only avoiding the increase of energy consumption caused by excessive bed resistance but also ensuring full contact between gas and catalyst.

Bulk density: 0.75±0.1Kg/L. The bulk density is uniform, and a dense and uniform bed can be formed during loading, avoiding gaps, ensuring the contact efficiency between feed gas and catalyst, and facilitating the calculation of loading capacity to adapt to catalytic reactors of different volumes.

Oxygen content of feed gas: ≤3%. It can treat feed gas with high oxygen content without pre-deoxidation treatment in advance, which greatly simplifies the production process and reduces the initial equipment investment; if the oxygen content of feed gas exceeds 3%, the deoxidation effect can be ensured to meet the standard by adjusting the space velocity or heating.

Deoxidation depth: ≤0.5×10⁻⁶V/V (i.e., ≤0.5ppm). The deoxidation precision is high, which can reduce the oxygen impurities in hydrogen to an extremely low level, meet the needs of fields such as electronics and scientific research that have high requirements on hydrogen purity, and ensure the subsequent product quality and production safety.

Service life: ≥3 years. Under normal working conditions (clean feed gas and compliant operating parameters), the catalyst can operate continuously and stably for more than 3 years. Compared with ordinary palladium catalysts, the service life is extended by more than 30%, which greatly reduces the replacement frequency and maintenance cost, and reduces the impact of shutdown on production.

Functions of Palladium Catalyst

The custom-made Pd-Al₂O₃ type palladium catalyst by Hongbo has the core function of hydrogenation and deoxidation. According to different application scenarios, it is mainly divided into two application functions, with simple and convenient operation process, adapting to different process requirements:

(1) Used for Deoxidation in Hydrogen

This catalyst is specially suitable for deep deoxidation treatment of hydrogen products in hydrogen production processes, and can be directly used to remove oxygen impurities from hydrogen to ensure hydrogen purity. Its deoxidation mechanism is catalytic conversion type, which does not need the assistance of chemical adsorption and other methods, can completely convert oxygen into water, and no secondary impurities are generated. Compared with traditional catalysts, the prominent advantage of this catalyst is that no complex activation treatment is required for the first use, which simplifies the start-up process: before use, it is only necessary to completely replace the air in the catalytic reactor bed with dry nitrogen (N₂) to avoid the mixture of oxygen and hydrogen in the bed forming explosive gas. After replacement, the feed gas can be directly introduced, and the catalyst can quickly start the catalytic reaction to achieve continuous deoxidation.

(2) Used for Hydrogenation and Deoxidation of Other Inert Gases

In addition to deoxidation in hydrogen, this catalyst can also be widely used for hydrogenation and deoxidation treatment of inert gases such as nitrogen, argon, and ammonia, which is suitable for production scenarios that require high-purity inert gases. The specific operation process is as follows: first, uniformly fill the catalyst into the catalytic reactor to ensure that the bed is flat and free of gaps; then completely replace the air in the bed with dry nitrogen to avoid oxygen and moisture in the air affecting the catalyst activity; after replacement, under normal temperature conditions, introduce pure hydrogen at a space velocity of 100~300hr⁻¹ for about 1~2 hours, trigger the catalytic activity of the catalyst through hydrogen, and complete the activation start-up; after activation, the inert gas containing oxygen impurities can be introduced, and the ratio of hydrogen to oxygen (H₂:O₂>2:1) can be controlled to ensure that oxygen can be completely converted, realize deep deoxidation of inert gases, and meet the requirements of subsequent production processes.

Application Fields of Palladium Catalyst

Hongbo Pd-Al₂O₃ type palladium catalyst (HM-1 type) has been widely used in many industrial fields relying on its excellent deoxidation performance, simple operation process and long service life, covering core fields such as metallurgy, chemical industry, scientific research and electronics, with broad application prospects. In the metallurgical industry, it is mainly used for deoxidation treatment of hydrogen protective atmosphere in metallurgy, ensuring that metal materials are not oxidized during the metallurgical process and improving product quality; in the chemical industry, it is suitable for chemical hydrogen production processes such as synthetic ammonia and methanol, removing oxygen impurities from hydrogen, avoiding impurities affecting chemical reaction efficiency and product purity, and can also be used in chemical production protected by inert gases to achieve deep gas purification; in the scientific research field, it is used in experimental scenarios such as laboratory hydrogen production and gas purification, providing high-purity hydrogen and inert gases for scientific research experiments and ensuring the accuracy of experimental data; in the electronic industry, it is used for gas purification in the production process of electronic components. High-purity hydrogen and inert gases can avoid oxidation of electronic components and improve the stability and service life of products. With the continuous improvement of requirements for gas purity in various industries, the application scenarios of this catalyst will be further expanded to provide support for the high-quality development of more industries.

Packaging and Storage Methods

To ensure the stable performance of the palladium catalyst and prevent moisture, pollution or damage during transportation and storage, professional packaging and storage methods are adopted: the catalyst is packaged in double-layer plastic bags hermetically, the inner layer is a leak-proof and waterproof PE bag, and the outer layer is a wear-resistant and moisture-proof nylon bag, which can effectively isolate air, moisture and impurities; the hermetically packaged catalyst is put into thickened cardboard barrels or iron barrels, the barrel mouth is sealed with a sealing cover, the barrel body is marked with product name, specification, production date, shelf life and other information, and shockproof and buffer filling materials are equipped to avoid collision and damage of catalyst particles during transportation. During storage, the well-packaged catalyst should be placed in a dry, ventilated and cool warehouse, away from water sources, fire sources and corrosive substances, to avoid catalyst activity attenuation caused by humid and high-temperature environments; at the same time, extrusion and collision of packaging barrels are prohibited to prevent catalyst particles from pulverizing; the unopened catalyst can have a shelf life of 12 months under the specified storage conditions, and should be used as soon as possible after opening to avoid long-term exposure to air affecting performance.